Improving sustainability is more important than ever for the transportation industry. A 2023 survey of 350 shippers and 150 carriers found that 94% of transport executives agree that reducing emissions is a top priority, largely because of consumer demand. In addition to evolving consumer expectations, federal and state regulations are key drivers for sustainability in trucking.

The survey referenced above also found that shippers would overwhelmingly prefer that their goods be moved via electric or alternative-fuel vehicles if carriers in their networks offered them. However, inflation, market uncertainty and the cost of new net-zero vehicles present a barrier to entry for many carriers, leaving them unable to meet the sustainability desires of their customers and potentially losing business to competitors that can.

In this period of transition, however, there are technology tools that can help bridge the gap between the diesel trucks of today and the electric and alternative-fuel vehicles of the quickly approaching future, empowering carriers to rein in emissions while improving overall operational sustainability and profitability.

EROAD stands at the forefront of empowering transformation within fleet management through powerful technology solutions. Here are just a few ways that our telematic devices and systems can improve sustainability efforts in the transportation industry, as well as the cold chain and construction segments.

Transportation

The transportation industry is a major contributor of greenhouse gas emissions (GHG) in the U.S. According to the Environmental Protection Agency, transportation contributes to 29% of all GHG emissions, with, light-, medium- and heavy-duty vehicles account for 81% of these emissions.

The primary solution for improving sustainability for transport fleets is reducing these emissions by controlling fuel use and increasing vehicle efficiency. Here’s how telematics can help in both areas:

Reduce emissions and fuel use

- EROAD’s connected platform provides fleet owners with the visibility and actionable insights needed to track fuel usage, emission rates and idling to identify where improvements can be made.

- The platform enables users to monitor fuel use and emissions by integrating fuel usage, observing vehicle utilization and monitoring driving behavior patterns.

- Using real-time route optimization and reporting, fleet managers can use this data to plan routes and cut down on idle times or inefficient routing.

- Dashcams and asset trackers also monitor driving behaviors that contribute to fuel waste (and vehicle wear and tear), such as long idle times, quick accelerations, sudden stops, and other harsh driving events.

Extend vehicle life and improve efficiency

- EROAD’s platform also streamlines maintenance plans, with service requests and inspection reminders to support vehicle performance.

- The platform provides fault code alerts and act before an incident occurs to avoid breakdowns, which can lead to wasted fuel and delivery delays.

- Monitor the health of your vehicles with the use of our IoT (Internet of Things) sensor network, asset trackers, and connected vehicle gateways devices.

Cold Chain

Temperature monitoring is crucial for cold chain fleets. The Food and Agriculture Organization estimates that about 39% of all food waste is caused by transportation issues, such as delays in delivery or reefer temperature fluctuations.

Reefer units can unexpectedly use substantial amounts of fuel if they are not maintained, which can seriously increase operating costs and hurt sustainability initiatives.

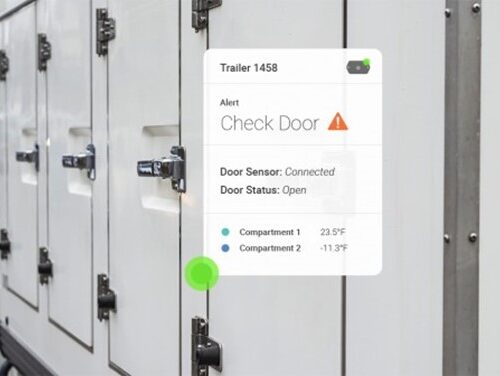

EROAD’s CoreHub Xtreme enables safety managers to monitor and control the efficiency and safety of their fleets on a single platform. Our unique CoreTemp™ solution uses a network of sensors and artificial intelligence to track load temperatures and provide real-time alerts for each compartment to maintain compliance.

Decrease food waste with live temperature monitoring

- With our fleet management platform, gateway devices, integrated IoT sensor network, and superior core product temperature verification, you can guarantee regulatory compliance and reduce product waste.

- Keep track of core product temperatures from each compartment in real-time.

- Remotely adjust reefer unit temperatures while recognizing and monitoring fluctuations.

- Manage FSMA compliance and reporting for reefer trailers by using our core product temperature monitoring and control toolsets, CoreTemp™, for advanced FSQA.

Improve reefer performance and efficiency

- Preserve the condition of your reefers with predictive shutdown alerts to keep your trailers healthy and prevent any issues on the road.

- Decrease operational costs such as fuel use, energy, and labor by knowing when to start pre-cooling your reefer units.

- Improve trailer utilization by standardizing set points, timing for when reefer units need to be activated, and ensuring the right equipment is assigned to the correct route.

Construction

A study conducted by McKinsey found that the construction industry itself makes up one-fourth of all global GHG emissions. About 13% of these emissions come from construction vehicles and a small portion from cement processing.

EROAD aims to help construction and ready-mix fleets reduce emissions and waste through more precise monitoring systems. Connected IoT sensors provide real-time updates to track vehicle location, fuel usage, and concrete moisture levels for more efficient asset utilization.

Less material waste through accurate concrete pours

- Improve overall quality while cutting waste by keeping an eye on count rotations, moisture levels, and fleet location.

- Use advanced AI to optimize the vehicle spacings when pouring concrete minimizing downtime and unnecessary emissions.

- Use geo-fencing to automate job status updates and decrease wait times by supporting more efficient planning and pouring.

Optimize sustainability by cutting down on driving and vehicle idling times

- EROAD’s CoreHub vehicle gateway utilizes a network of IoT sensors and a direct connection the engine control module (ECM) to provide key data on fuel utilization, idle times, and other driving behavior factors contributing to emissions.

- Employ real-time, comprehensive analytics and reporting to create a more streamlined project delivery, reducing fuel consumption.

- Generate energy consumption reports for vehicle performance insights.