Cold Chain Temperature Monitoring

Real-time monitoring of refrigerated assetsMoving more than 70 percent of the nation’s freight, the trucking industry is the driving force behind the U.S. economy. And when it comes to transporting perishable foods, motor carriers also play a major role in protecting the public’s health. Carriers are a key link in the cold chain, the process by which temperature-sensitive products make it safely from processing to end users, such as grocery stores and restaurants.

To ensure the safety of the temperature-sensitive products they haul and to comply with government regulations, carriers must maintain the appropriate temperatures in their refrigerated trailers. In this guide, we’ll provide an overview of the cold chain and the related regulations as well as cold chain temperature monitoring and technology solutions that can help carriers stay in compliance, reduce waste and make better business decisions.

What is the cold chain?

The cold chain is a temperature-controlled supply chain. It involves the end-to-end temperature management of perishable commodities, such as food, beverages, pharmaceuticals and other temperature-sensitive products. The cold chain begins at production and processing and must be maintained through final delivery.

Transportation of temperature-sensitive products from processing plants to distribution centers and end users, such as grocery stores, is a crucial link in the cold chain. To safely transport temperature-sensitive products – most often food, according to the American Trucking Associations’ Technology & Maintenance Council – motor carriers use refrigerated trailers (also called reefers) to ensure that products are kept at the correct temperature.

Carriers also must keep records of the reefer temperature throughout transport. Traditionally, this entailed drivers stopping periodically to manually check the trailer temperature and recording it in a paper log. Today, however, technology solutions support more consistent, accurate and convenient reefer trailer temperature monitoring, helping carriers better ensure the safety of food and other temperature-sensitive products, reduce waste, avoid rejected loads, stay in compliance with government regulations, and increase customer satisfaction.

Why is cold chain temperature monitoring important?

Each year in the U.S., tens of millions of people suffer from foodborne illness, with 128,000 people being hospitalized with foodborne diseases and 3,000 people dying, the Centers for Disease Control estimates.

While not all instances of foodborne illness can be traced to how the food was transported, maintaining proper temperature during transport can help prevent the growth of harmful bacteria that make people sick. Cold chain temperature monitoring, then, is crucial to ensuring that food products that require refrigeration are safe for consumers. And it helps carriers reduce the expense – and damage to their business reputation – associated with spoilage, waste and rejected loads.

Food safety regulations also require trailer temp monitoring. Among the most significant of these regulations is the Food Safety Modernization Act (FSMA), which was signed into law in 2011. One FSMA provision – the Sanitary Transportation of Human and Animal Food Rule – requires carriers to maintain “adequate temperature controls.” Carriers must also keep temperature records that show that appropriate temperature ranges were maintained during a trip.

What is trailer temp monitoring?

Trailer temp monitoring entails tracking reefer trailer temperature to ensure that it is maintained at an appropriate level for the products being shipped. Failure to adequately track and maintain the reefer temperature can cause problems for consumers and carriers.

For consumers, unsafe temperature fluctuations during transport can raise the risk of foodborne illness, should the food make it to store shelves or restaurant kitchens. For carriers, it can result in loads being rejected, which is costly in a variety of ways, and can have a negative impact on future business opportunities.

Carriers use a variety of tools and methods to monitor reefer trailer temperatures, including temperature sensors, automated alerts for temperature fluctuations, manual temperature checks of products in transit and, increasingly, technology that uses advanced algorithms and artificial intelligence.

What Role Does Artificial Intelligence Play in Cold Chain Temperature Monitoring?

Artificial intelligence (AI) is revolutionizing reefer trailer temperature monitoring. This advanced technology helps carriers:

- Increase operational efficiency

- Reduce costs

- Improve temperature control

- Improve the performance of perishable products

- Meet (and exceed) customer requirements

- Achieve regulatory compliance

Key AI applications for cold chain temperature monitoring include:

Real-time monitoring: AI continuously monitors reefer temps (and even individual compartments within a reefer trailer) in real time. AI algorithms collect and analyze temperature data throughout transit, providing have real-time visibility into the condition of the perishable goods being transported.

Elimination manual temperature checks: By supplying accurate core temperature predictions, AI solutions like EROAD’s CoreTemp eliminate the need for manual probing of products, reducing costs and eliminating the potential for human error or intentional falsification.

Predictive analytics and alerts: AI can compare real-time temperature readings with predefined thresholds and expected temperature patterns to identify and predict potential issues like temperature excursions, equipment malfunctions or door openings. Automated alerts can then be generated to notify relevant personnel, enabling timely actions to mitigate risks and ensure product quality.

Choosing a cold chain temperature monitoring solution

Given the importance of cold chain temperature monitoring, many carriers are opting to automate truck temperature monitoring by adding reefer trailer management solutions to their fleets.

Reefer trailer temperature monitoring technology can help carriers more easily ensure proper temperature during transport and collect required temperature information – protecting consumers’ health and carriers’ bottom line. Beyond that, a technology solution can send customizable alerts to fleet managers and drivers that there is a potential issue with a reefer trailer, allowing them to fix the problem before the load is lost.

Reefer monitoring technology has revolutionized cold chain logistics, and carriers that implement it have a competitive advantage over those that don’t. However, not all solutions are created equal. Here are some key considerations to keep in mind when selecting a reefer trailer temperature monitoring solution.

- Compliance: Does the solution have the features you need to be compliant with FSMA regulations?

- Advanced monitoring: Does the solution incorporate the latest technology, such as artificial intelligence, to empower you to improve your operations, reduce expenses and exceed customer expectations?

- Two-way control: Does the solution allow you to control the reefer remotely?

- Reefer unit integration: Is the solution compatible with refrigeration units made by major manufacturers?

- Ruggedness: Is the solution built to stand up to the harsh environments in which you operate?

- Ease of installation: Can you install the solution quickly and get your reefers back on the road?

- Longevity: Is the solution designed to adapt and expand as new sensors and technologies become available?

- Actionable data: Does the solution provide actionable insights about operational trends – such as fleet and reefer utilization, fuel and battery usage, and maintenance issues – that help you make better business decisions?

Related Information

How Reefer Trailers Are Monitored

Motor carriers are responsible for ensuring that perishable goods are transported safely, at the correct temperature and in compliance with regulatory requirements. In this article, we’ll cover the primary ways that carriers monitor reefer containers to ensure that proper temperatures are maintained.

Ensure Food Safety and Compliance with Reefer Telematics

Carriers that transport food and beverages – especially those hauling perishable goods in refrigerated trailers (reefers) – are a crucial link in ensuring the safety of the food in the cold chain, and they must comply with FSMA regulations to ensure their cargo is are delivered safely for consumers.

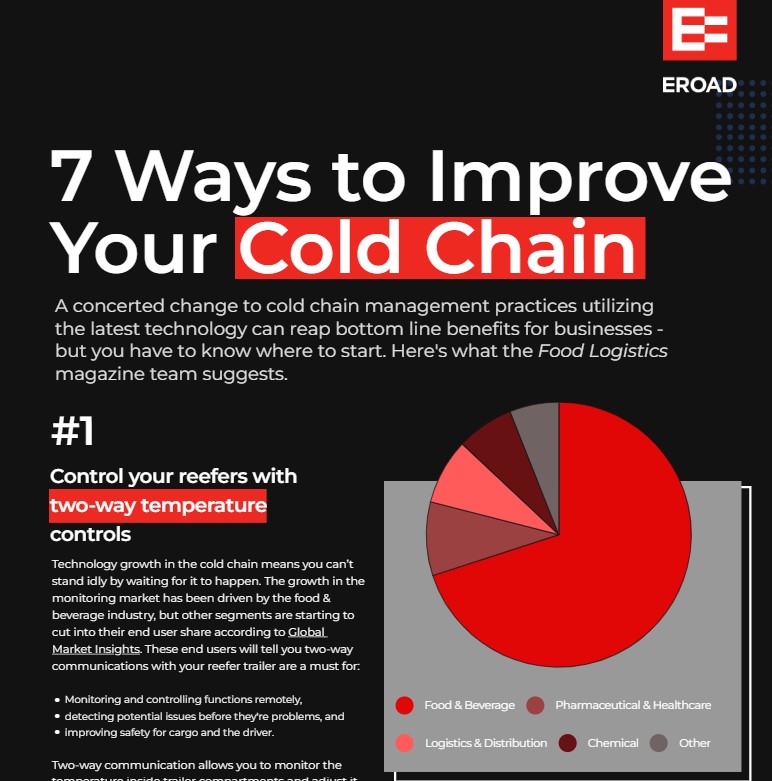

7 Ways to Improve Your Cold Chain

A concerted change to cold chain management practices utilizing the latest technology can reap bottom line benefits for businesses – but you have to know where to start. Check out this infographic highlighting what the Food Logistics magazine team suggests you look at to improve your cold chain.

Reduce Reefer Fuel and Waste Costs with CoreHub Xtreme

When left unchecked, reefer units can run through unexpected amounts of fuel, significantly impacting your bottom line. Inefficient pre-cooling, trailers being used unexpectedly as storage units, and trailers getting lost in the yard are all common ways to rack up an expensive fuel bill.