It’s time to revisit how your refrigerated goods are monitored

Go beyond the temperature probe. Unlock new insights with artificial intelligence and a shared cold chain platform to keep your operations moving and customers happy.

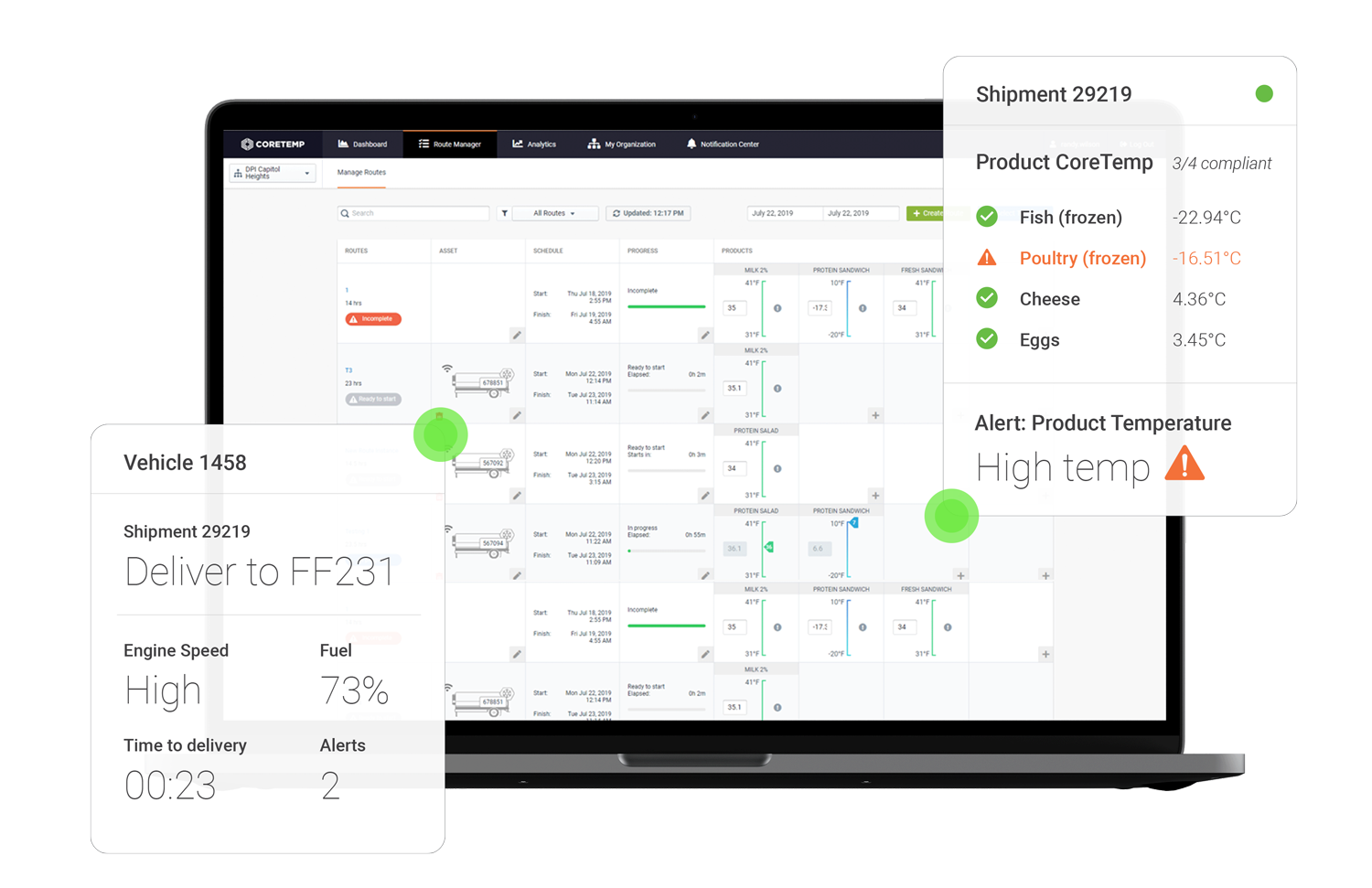

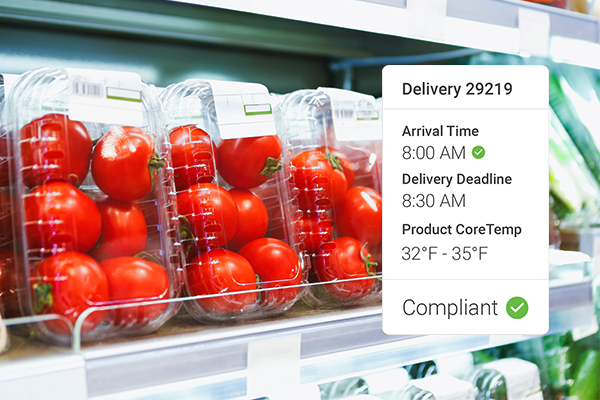

Simplify compliance with core product temperature insights

Monitor core product temperatures with artificial intelligence

| Eliminate the need for manual product temperature probing | |

| Multi-layered temperature warnings and alerts per compartment | |

| Real-time route breakdown and performance score updates | |

| Ensure compliance, save time, reduce costs and keep customers happy |

Getting going is simple

1.

Install and gather temperature data

2.

Assign trailers to routes and products

3.

Set product temperatures

4.

Monitor performance and watch compliance scores climb

5.

Share with your customers to provide real-time visibility and boost satisfaction

Have a competitive edge throughout your cold chain

Promote transparency between shippers, carriers, and distributors

Our shared platform gives you full control of your cold chain distribution network and gives your customers real-time visibility into route compliance, product temperatures and a full suite of dashboards. EROAD customers are using tomorrow’s cold chain technology to drive positive change in their processes today.

“By using EROAD as part of our new predictive product temperature monitoring process we were able to save about $50,000 per month by not requiring drivers to probe product at each stop.”

Tim Bates, Corporate Quality Systems Director – Logistics

Golden State Foods

“With that data, we went from 21 minutes average stop time per day and knocked that down under 18 minutes per day. We beat our goal of $80,000; we were able to realize cost savings over $200,000..”

Robert Forte, Division Vice President

E.A. Sween Company

Ensure food safety, extend the life of your assets, and reduce lost loads

Have predictive insights, learn and respond in real-time, and spend less time manually diagnosing

Reduce claims and minimize the risk of spoiled goods by responding to alerts in real-time. With alerts for everything from OEM Fault codes to ELD violations, harsh cornering and temperature variations, you’ll have confidence in the health of your assets, quality of the loads you deliver, and ability to intervene before an incident requires escalating.

Original Equipment Manufacturers (OEMs)

What is FDA’s New Era of Smarter Food Safety?

Our free guide explores how this blueprint is changing how the American food industry thinks about safety, from government and organizational level through to the consumer.

All sections of the FDA’s blueprint are clearly explained, informing you of everything you need to know and as we move into the future.

Unlock the EROAD Difference

| Trailer Tracking | Two-Way Reefer Control | Reefer Fuel & Battery Life Monitoring | Predictive Shutdown Insights & Alerts | Compartment Temperature Monitoring | Shared Platform for Shippers, Carriers, and Distributors | Product Specific Temperature Monitoring | |

| EROAD |  |

|

|

|

|

|

|

| Other Providers |  |

Not with all major reefer brands | Some | Some | Some | Some |  |

| EROAD | Other Providers | |

| Trailer Tracking |  |

|

| Two-Way Reefer Control |  |

Not with all major reefer brands |

| Reefer Fuel & Battery Life Monitoring |  |

Some |

| Predictive Shutdown Insights & Alerts |  |

Some |

| Compartment Temperature Monitoring |  |

Some |

| Product Specific Temperature Monitoring |  |

|

| Shared Platform for Shippers, Carriers, and Distributors |  |

|

Featured Articles

Recent news, blog posts and case studies

Case Study

Artificial Intelligence in Cold Chain Removes Need for Manual Probing

CoreTemp, an AI-driven reefer solution results in the elimination of manual temperature checks and significant cost savings for QCD.

Blog

Understanding the Adverse Driving Condition Exception

Where there are rules, there are often exceptions – here is what you need to know about the adverse driving condition exception.